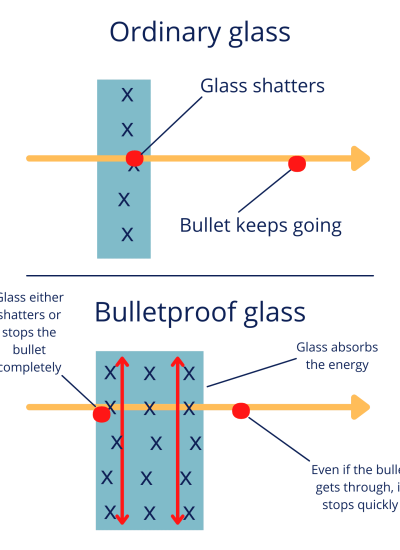

In today’s world, security and safety have become paramount concerns in various industries. Among the many advancements in protective measures, bulletproof glass stands as a remarkable innovation. Also known as ballistic glass or bullet-resistant glass, it’s a specialized material designed to resist or mitigate the impact of bullets or projectiles.

Bulletproof glass is a critical component in enhancing safety and security across various industries. Its ability to provide protection against ballistic threats while offering transparency makes it an essential material in safeguarding lives and assets in high-risk environments. As technology advances, ongoing innovations in material science continue to improve the effectiveness and versatility of bulletproof glass in various security applications.

Types of Bulletproof Glass:

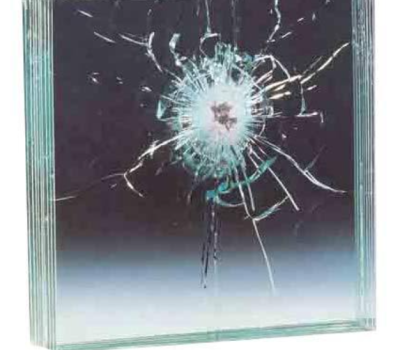

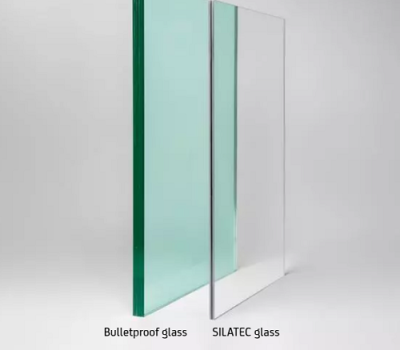

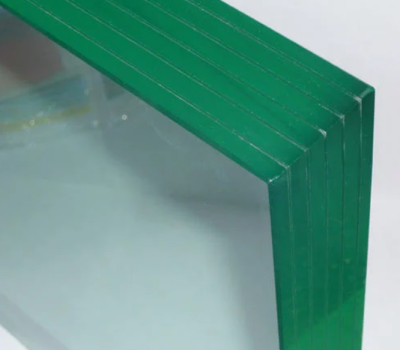

Laminated Glass: The most common type, made by bonding multiple layers of glass together with a strong, transparent interlayer, usually made of polyvinyl butyral (PVB) or ethylene-vinyl acetate (EVA). This design prevents the glass from shattering upon impact, ensuring it remains intact even when pierced.

Polycarbonate Thermoplastic: Utilizes layers of polycarbonate, a tough and resilient material, offering excellent impact resistance. Often used in combination with other materials, such as glass or acrylic, to create a multi-layered composite.

Acrylic: Acrylic-based bullet-resistant materials are lightweight and possess good optical clarity. They are used as an alternative to traditional glass-based solutions.