Toughened bent glass, also known as tempered bent glass, is a type of glass that is heat-treated to increase its strength and resistance to breakage. This process involves heating the glass to a high temperature, typically around 600 to 700 degrees Celsius, and then rapidly cooling it with jets of cold air. This causes the surface of the glass to cool and solidify more quickly than the interior, creating compressive stress on the surface and tensile stress in the core of the glass.

The result is a glass that is up to five times stronger than untreated glass of the same thickness, making it more resistant to impact, thermal shock, and bending. Additionally, if the glass does break, it will shatter into small, blunt pieces rather than sharp shards, which reduces the risk of injury.

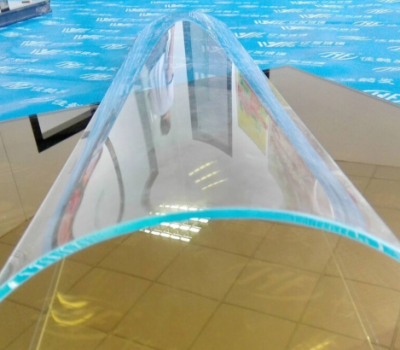

Toughened bent glass can be formed into a variety of shapes and sizes to meet the needs of various applications, from curved glass facades and balustrades to shower enclosures and automobile windows. It is also commonly used in commercial and industrial settings where safety and durability are paramount.

Overall, toughened bent glass is a highly versatile and durable material that offers superior strength, safety, and aesthetic appeal.